Daclatasvir is a crucial antiviral drug prominently used in hepatitis C therapy. Ensuring the purity of Daclatasvir is essential to guarantee its safety and efficacy, as even trace amounts of unintended compounds can impact the patient’s health. Daclatasvir Impurities are chemical entities that may be present alongside the active pharmaceutical ingredient due to various factors like manufacturing processes, degradation, or raw materials. These impurities, if not controlled, can compromise the drug’s quality and lead to adverse effects or regulatory issues.

At Aquigen Bio Sciences, a wide range of Daclatasvir impurity standards are developed to facilitate reliable quality testing. Stringent monitoring of such impurities forms a backbone for regulatory compliance, making their evaluation a fundamental step in drug production and approval. Let’s explore Daclatasvir impurities in detail.

Understanding Daclatasvir Impurities

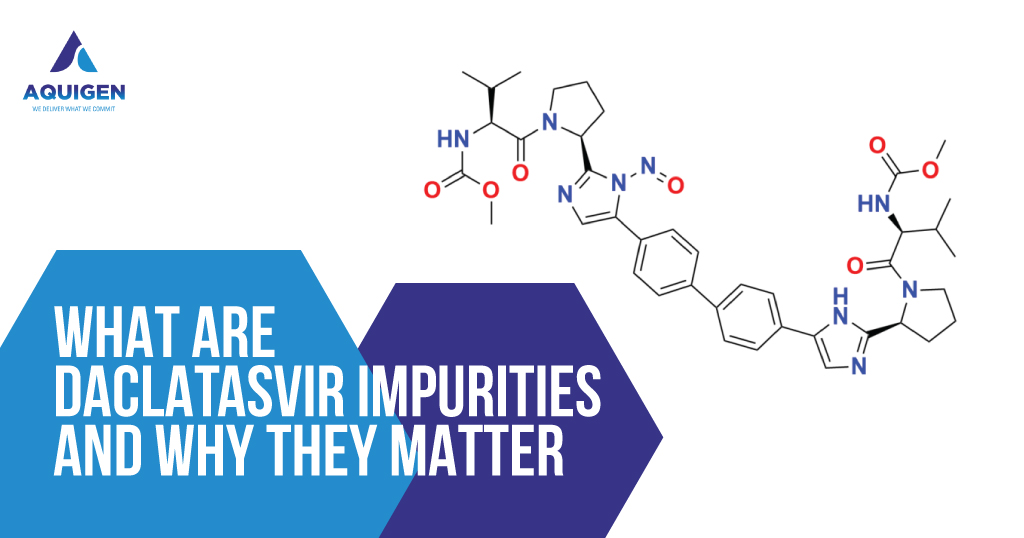

Daclatasvir, typically manufactured and used as Daclatasvir Dihydrochloride, undergoes various synthetic and formulation processes before reaching the market. During these processes, several types of impurities can arise. Daclatasvir Impurities refer to any unwanted chemicals, either arising from the manufacturing process or developing during storage and handling. These impurities are broadly categorized as:

- Organic Impurities (process-related or degradation)

- Inorganic Impurities (residual reagents, salts)

- Residual Solvents

- Special Cases: Nitroso impurities and other by-products

Each category poses distinct analytical and quality control challenges. Regulatory authorities such as the US FDA, EMA, and CDSCO in India require comprehensive identification, quantification, and control of all impurities.

Daclatasvir Impurities: Types and Significance

The pharmaceutical industry closely monitors specific impurities in Daclatasvir for their potential effects on safety and drug stability:

- Daclatasvir Impurity 1 and Daclatasvir Impurity 2: These are structurally related compounds resulting from side reactions or incomplete conversions during synthesis. These impurities may impact the drug’s efficacy if present above certain thresholds or, worse, pose safety risks due to unforeseen toxicological responses.

- Daclatasvir Nitroso Impurity, including Daclatasvir Nitroso Impurity 1 and Daclatasvir Nitroso Impurity 2: Nitroso impurities, in particular, have gained heightened regulatory scrutiny. The presence of trace levels of nitrosamines in pharmaceutical products is a well-documented issue that has resulted in the recall of several drugs globally. Nitrosamines and their congeners, such as Daclatasvir Nitroso Impurity 2, are considered probable human carcinogens. Their detection and control have become a top priority for regulatory agencies.

- Degradation Products: Daclatasvir, in its Diclatasvir Dihydrochloride form, may degrade under stress conditions (such as extreme pH, heat, or light), leading to new impurities. These degradation-related Daclatasvir Impurities are evaluated for their impact on the active pharmaceutical ingredient’s quality attributes.

Analytical Strategies for Identifying Daclatasvir Impurities

Quality control of Daclatasvir Impurities relies heavily on advanced analytical techniques such as HPLC, GC-MS, LC-MS/MS, and NMR spectroscopy. These methods are employed for:

- Accurate identification and structural elucidation of Daclatasvir Impurity 1, Daclatasvir Impurity 2, and nitroso variants.

- Quantification at trace levels as required by ICH Q3A/B guidelines.

- Purity profiling to monitor levels during stability studies and product shelf life.

The analytical standards used for these impurities must meet stringent specifications to ensure reliable results. Impurity standards providers, like those at Aquigen Bio Sciences, produce certified reference materials that guarantee traceability, reproducibility, and compliance for pharmaceutical analysis.

Why Controlling Daclatasvir Impurities Matters

- Patient Safety: The foremost reason for controlling Daclatasvir Impurities is safety. Impurities, especially nitroso and degradation products, can be highly toxic even at low concentrations. Oversight or inadequate control could lead to adverse effects in patients.

- Regulatory Compliance: Global health authorities maintain strict requirements for the control, reporting, and qualification of pharmaceutical impurities. Companies must demonstrate that every batch of Daclatasvir, especially Daclatasvir Dihydrochloride, remains within permissible impurity limits.

- Drug Efficacy and Quality: Some impurities can reduce the potency or bioavailability of Daclatasvir, affecting treatment outcomes. Others may interact with excipients or packaging, contributing to product instability or reduced shelf life.

- Reputation and Market Access: Regulatory recalls or failed batches due to impurity problems can damage a company’s reputation and delay or block market approvals. Therefore, investing in reliable impurity standards and thorough testing is not just a regulatory necessity but a strategic advantage.

The Role of Reference Standards in Managing Daclatasvir Impurities

Reference standards are the backbone of reliable impurity testing. For Daclatasvir, the need for highly pure, accurately characterized Daclatasvir Impurity 1, Daclatasvir Impurity 2, and Nitroso impurities is paramount. CROs like Aquigen Bio Sciences enable pharmaceutical manufacturers and quality control labs to:

- Develop robust impurity testing methods

- Calibrate analytical instruments with validated standards

- Meet global regulatory and pharmacopoeial requirements

Certified impurity standards ensure that the quantification of even trace levels of Daclatasvir Nitroso Impurity 1 and Daclatasvir Nitroso Impurity 2 is accurate and defensible in audits or regulatory submissions.

Trust the Leading Daclatasvir Impurity Standards Provider in India

Impurity profiling is not merely a regulatory mandate; it is a safeguard for patient wellbeing and the reputation of the generic pharmaceutical sector. For complex molecules like pregabalin, understanding and controlling the impurity landscape is critical. From common process impurities to specialized substances like Pregabalin Impurity 48, Pregabalin, and Pregabalin EP Impurity D (R Isomer), meticulous analysis ensures the safety, efficacy, and success of generic products.

Aquigen Bio Sciences is recognized as the leading provider of Pregabalin impurity standards in India, supporting global pharmaceutical companies with a robust catalogue of impurity standards and analytical materials. Our Pregabalin Impurity portfolio covers the large spectrum of pregabalin-related substances, including rare isomers and specific degradation products.

By choosing Aquigen Bio Sciences, generic manufacturers benefit from rapid access to an extensive library of impurity standards, expert support in analytical method development and validation, confidence in regulatory submission and ongoing product quality. Get in touch with us today!