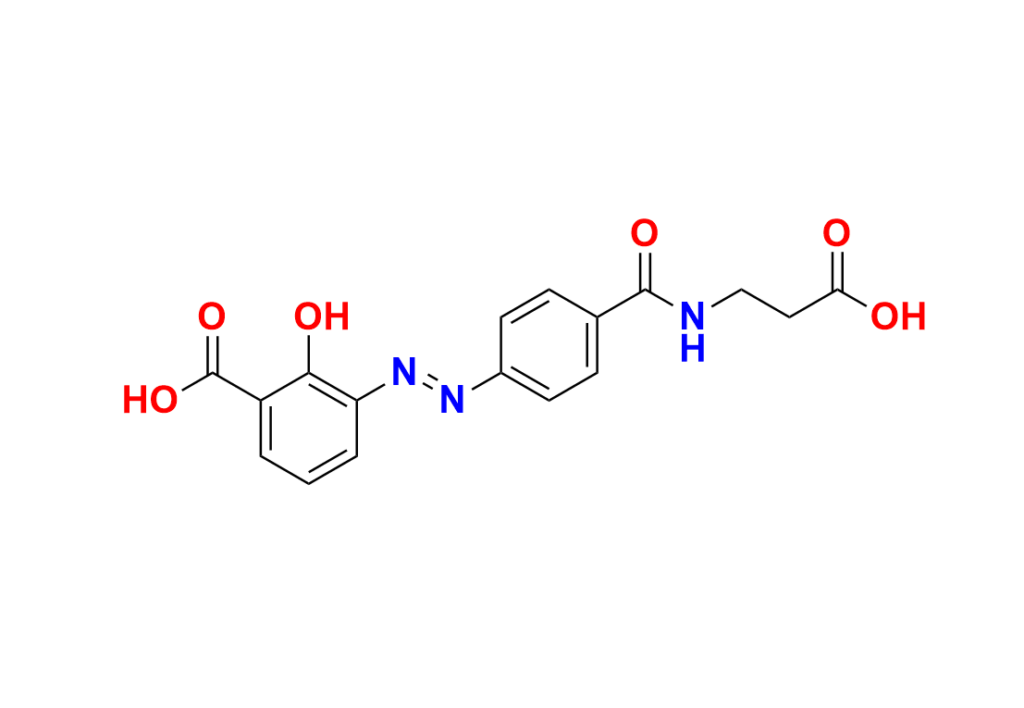

Balsalazide USP Impurity 2

In Stock

| CAT NO | AQ-B000512 |

|---|---|

| CAS NO | 1242567-09-4 |

| Mol.F | C17H15N3O6 |

| Mol.Wt | 357.32 |

| Availability | In Stock |

| Chemical name | 3-((4-((2-Carboxyethyl)carbamoyl)phenyl)diazenyl)-2-hydroxybenzoic acid |

Ready To Dispatch Within 24 Hours

In Stock

Request for Quotation :

Balsalazide USP Impurity 2

Product Description

Balsalazide USP Impurity 2 is a high-quality reference standard supplied with comprehensive characterization data, ensuring compliance with regulatory guidelines. This product is essential for analytical method development, method validation (AMV), quality control (QC) applications, and plays a crucial role in Abbreviated New Drug Applications (ANDA).

Balsalazide USP Impurity 2 can be used as a reference standard, with possible traceability to pharmacopeial standards such as USP or EP, based on feasibility. AquigenBio products are strictly for analytical purposes and is not intended for human use.

Applications of Balsalazide USP Impurity 2:

1. Pharmaceutical Impurity Profiling

-

Used as a recognized compendial impurity of Balsalazide, listed in the USP monograph.

-

Assists in identifying and quantifying trace-level impurities in:

-

Balsalazide Active Pharmaceutical Ingredient (API)

-

Balsalazide drug formulations

-

2. Analytical Method Development & Validation

-

Serves as a certified reference standard for method development using:

-

HPLC

-

LC-MS/MS

-

UPLC and GC (where applicable)

-

-

Supports validation of:

-

Specificity

-

Limit of Detection (LOD) / Limit of Quantification (LOQ)

-

Linearity and accuracy in impurity testing

-

3. Regulatory Compliance (ICH & USP)

-

Required for impurity analysis to meet:

-

ICH Q3A/B guidelines on impurity limits

-

USP and FDA requirements for known related substances

-

-

Used in:

-

ANDA filings

-

DMF submissions

-

Pharmacopoeial dossiers

-

4. Stability & Degradation Studies

-

Applied in forced degradation and stability testing of Balsalazide formulations.

-

Helps track the formation and concentration trends of Impurity 2 under:

-

Oxidative, hydrolytic, photolytic, and thermal stress

-

5. Routine Quality Control (QC) Testing

-

Used during:

-

Batch release testing

-

In-process QC

-

Finished product analysis

-

-

Ensures impurity levels are within acceptable pharmacopeial limits across all production batches.

6. Research & Development

-

Utilized in pharmaceutical R&D labs, contract research organizations (CROs), and academic institutions to:

-

Study impurity pathways and mechanisms

-

Explore degradation profiles

-

Optimize synthetic processes

-

⚠️ Note: This impurity is intended strictly for analytical and research use only. Not for human or veterinary use.

Safety & Handling Information for Chemical Products

1. Read the Safety Data Sheet (SDS) : The SDS contains important safety information for handling procedures, first-aid measures, disposal instructions, etc. Read it carefully.

2. Wear Personal Protective Equipment (PPE) : Always wear PPE as indicated in the SDS and by the manufacturer. This may include safety goggles, gloves, lab coats, respirators, and protective clothing.

3. Handle with Care : Be careful with chemical products - prevent spills, splashes, or inhaling fumes or dust. Use secondary trays or spill kits during chemical transfer or dispensing.

4. Work in a Well-Ventilated Area : Use chemical products in well-ventilated spaces to reduce vapour or gas exposure. Indoors, ensure ample ventilation via mechanical systems, fume hoods, or open windows and doors.

5. Avoid Mixing Chemicals : Avoid mixing chemical products unless directed by the manufacturer or a qualified professional. Incompatible mixes can lead to hazardous reactions, toxic gas releases, or explosions.

6. Labeling and Storage : Label chemical containers with product names, hazards, and handling information. Store in original or approved containers.

7. Prevent Contamination : Prevent cross-contamination with dedicated equipment or thorough decontamination. Keep food, drinks, and personal items away from chemical storage or work zones.

8. Emergency Procedures : Learn emergency procedures for spills, leaks, fires, or exposure incidents. Keep spill control materials, fire extinguishers, and emergency eyewash/shower facilities accessible.

9. First Aid : Know first aid for chemical exposure (eye contact, skin contact, inhalation, and ingestion). Ensure accessible supplies and trained personnel for assistance.

10. Proper Waste Disposal : Ensure chemical waste disposal as per local regulations; segregate hazardous from non-hazardous waste for health and environmental protection.

11. Training and Education : Offer thorough training to chemical handlers, covering usage, hazards, safety, and emergency response.

12. Report Incidents and Near Misses : Report incidents, near misses, spills, or safety concerns promptly to authorities and supervisors for investigation and action. By following these safety and handling guidelines, you can minimize risks associated with chemical products and create a safer work environment for yourself and others.

Read more

Wash thoroughly after handling. Remove contaminated clothing and wash before reuse. Avoid contact with eyes, skin, and clothing. Avoid ingestion and inhalation.