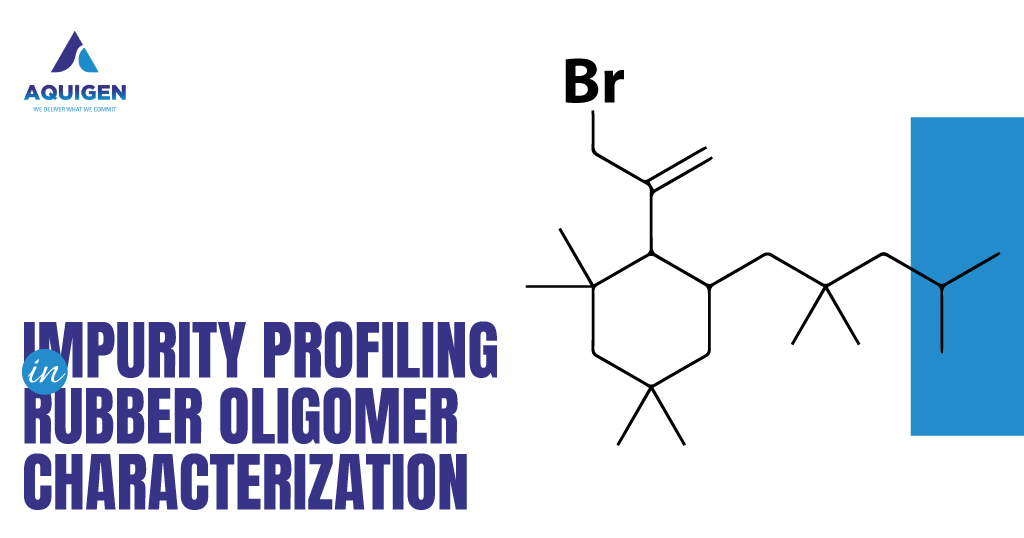

Rubber oligomers are short-chain polymeric materials derived from various monomers, such as isoprene, butadiene, and styrene. These oligomers are widely used in a variety of applications, including adhesives, sealants, coatings, and rubber products. However, the presence of impurities in rubber oligomers can significantly impact their performance, stability, and safety. Impurity profiling is, therefore, a critical aspect of rubber oligomer characterization to ensure the quality and consistency of the final product.

Importance of Impurity Profiling in Rubber Oligomer Characterization

Regulatory Compliance

Impurity profiling is essential for ensuring regulatory compliance, as governing bodies, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have established strict guidelines for the identification and control of impurities in pharmaceutical and related products. Accurate impurity profiling helps manufacturers demonstrate the purity and safety of their rubber oligomer-based products, meeting regulatory requirements and maintaining market access.

Quality Control and Assurance

Impurity profiling plays a crucial role in the quality control and assurance processes for rubber oligomers. By identifying and quantifying the presence of impurities, manufacturers can make informed decisions about product quality, process optimization, and the need for further purification steps. This helps ensure the consistent performance and reliability of rubber oligomer-based products.

Process Development and Optimization

Impurity profiling can provide valuable insights into the manufacturing process, allowing researchers and developers to identify potential sources of impurities, evaluate the effectiveness of purification methods, and optimize the overall production process. This knowledge can lead to improved product quality, increased yields, and reduced manufacturing costs.

Safety and Toxicological Considerations

Some impurities in rubber oligomers may have potential toxicological or safety implications, either for the end-users or the environment. Impurity profiling helps identify and address these concerns, ensuring the safe handling, storage, and application of rubber oligomer-based products.

Analytical Techniques for Impurity Profiling in Rubber Oligomer Characterization

Gas Chromatography-Mass Spectrometry (GC-MS)

GC-MS is a powerful analytical technique that combines the separation capabilities of gas chromatography with the structural elucidation capabilities of mass spectrometry. It is widely used for the identification and quantification of volatile and semi-volatile impurities in rubber oligomers, such as residual monomers, solvents, and other organic compounds.

Liquid Chromatography-Mass Spectrometry (LC-MS)

LC-MS is particularly useful for the analysis of higher molecular weight, less volatile, and thermally labile impurities in rubber oligomers. This technique can provide detailed information about the identity and relative abundance of these impurities, which are often challenging to analyze using GC-MS.

Nuclear Magnetic Resonance (NMR) Spectroscopy

NMR spectroscopy is a versatile analytical tool that can provide comprehensive structural information about rubber oligomers and their impurities. It can be used to identify and quantify a wide range of impurities, including residual monomers, oligomers, and other organic compounds.

Fourier-Transform Infrared (FT-IR) Spectroscopy

FT-IR spectroscopy is a complementary technique that can be used to identify functional groups and structural features of rubber oligomers and their impurities. It can provide valuable information about the chemical composition and purity of the sample.

Challenges and Considerations in Impurity Profiling of Rubber Oligomers

- Complexity of Rubber Oligomer Composition: Rubber oligomers can be composed of a wide range of monomers and can have various degrees of polymerization, leading to a complex mixture of compounds that can be challenging to analyze and characterize.

- Diversity of Impurities: Rubber oligomers can potentially contain a diverse range of impurities, including residual monomers, solvents, catalysts, and byproducts of the manufacturing process, each requiring specific analytical approaches for their identification and quantification.

- Trace-Level Impurities: Many of the impurities in rubber oligomers may be present at trace levels, requiring highly sensitive and selective analytical techniques for their reliable detection and quantification.

- Matrix Effects: The complex matrix of rubber oligomers can pose challenges in terms of sample preparation and data interpretation, as the presence of various components can potentially interfere with the analysis of impurities.

- Method Development and Validation: Developing and validating robust and reliable analytical methods for impurity profiling of rubber oligomers can be a time-consuming and resource-intensive process, requiring a thorough understanding of the sample characteristics and the limitations of the available analytical techniques.

Choose Aquigen Bio for Impurity Profiling

Impurity profiling is a critical aspect of rubber oligomer characterization, as it helps ensure the quality, safety, and regulatory compliance of these materials. By utilizing advanced analytical techniques, such as GC-MS, LC-MS, NMR spectroscopy, and FT-IR spectroscopy, manufacturers and researchers can establish a comprehensive understanding of the impurity profile of rubber oligomers, enabling them to optimize their manufacturing processes, ensure product quality, and meet regulatory requirements.

At Aquigen Bio Sciences, an API impurities Manufacturer and Supplier in India, we have extensive experience in providing impurity profiling services for a wide range of materials, including rubber oligomers. Our team of highly skilled analytical chemists and scientists is dedicated to delivering accurate and reliable results, helping our clients make informed decisions and maintain the highest standards of product quality and safety. If you have any questions or require assistance with your rubber oligomer characterization needs.